Sulfur Coated Urea: A Slow-Release Fertilizer Alternative

Background on Conventional Urea

Urea has long been one of the most widely used nitrogen fertilizers for crops due to its high nitrogen concentration of 46%. However, a major drawback of conventional prilled or granular urea is that it is readily soluble in water and can break down quickly, resulting in a large portion of the nitrogen being lost through volatilization or leaching within days of application. This necessitates multiple applications over the course of a growing season to provide plants with a steady supply of nitrogen. Frequent applications increase the costs for farmers and also risk environmental harm from excess nitrogen runoff.

The Development of Sulfur Coated Urea

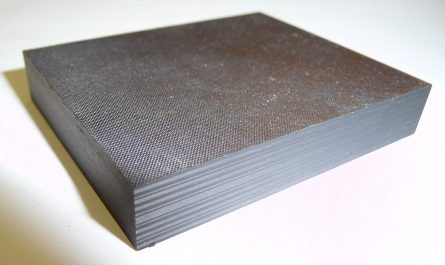

To address these issues, researchers in the 1960s began experimenting with coatings for urea to control its nitrogen release rate when used as a fertilizer. One of the most promising approaches involved encapsulating urea granules within a semi-permeable sulfur coating. The sulfur forms a water-resistant but gas-permeable layer that allows only a controlled diffusion of ammonia gas from the urea over a period of months. This results in a slow and prolonged release of nitrogen for plant uptake.

By the 1980s, the technology was scaled up for widespread commercial production. Today, sulfur coated urea (SCU) has become a major advanced fertilizer product used globally, competing strongly with other controlled-release nitrogen fertilizers. It provides farmers with an economically viable alternative to multiple applications of conventional urea while mitigating risks to the environment.

Mechanism of Nitrogen Release from SCU

At the molecular level, the nitrogen release mechanism from SCU works as follows:

– Water can slowly penetrate through the micropores in the hard sulfur coating that encases the urea granule.

– The water reaching the urea hydrolyzes it enzymatically to ammonium and carbon dioxide.

– Ammonium then diffuses out of the coating as ammonia gas due to the higher pH inside the granule.

– However, the sulfur coating prevents rapid diffusion and loss of ammonia to the atmosphere. It regulates the release over an extended time by slowing but not stopping the gas permeation process.

– Plant roots are able to absorb the ammonium/ammonia as it is released from the coating, providing a steady supply of nitrogen for 6-9 months on average after a single application.

Advantages of SCU over Conventional Urea

Some key advantages that SCU offers farmers and the environment compared to traditional urea include:

– Prolonged nitrogen supply: Single application of SCU provides crop-available nitrogen for the entire growing season, eliminating needs for multiple applications.

– Reduced leaching and runoff losses: By slowing nitrogen release, SCU helps prevent excess losses due to volatilization or being washed away from the soil by rain.

– Increased nitrogen use efficiency: More of the applied nitrogen is taken up by crops rather than lost to the environment. Studies have found efficiency gains of 10-30% with SCU.

– Low manufacturing costs: At around $20-30/ton more than urea, the marginal expense of the sulfur coating delivers significant agronomic and environmental benefits.

– Simple to use: SCU granules are surface applied to soil like regular fertilizers, while providing agronomic advantages of a controlled-release product.

Ideal Uses of SCU in Agriculture

While SCU delivers benefits across many major food, fiber and biofuel crops, some key applications where its advantages truly shine include:

– Rice: Rice crops absorb most of their nitrogen during periods of active tillering and panicle initiation. SCU precisely meets these discrete demand periods.

– Wheat: Its spring growth flush is well-supported by SCU, which then provides additional nitrogen into grain filling later in the season.

– Corn: Split applications of SCU boosts corn yields by satisfying nitrogen demands at different growth stages without risk of losses from single large doses.

– Turfgrass: The prolonged greening effect of SCU avoids frequent topdressing needs for lawns, parks and sports fields.

– Fruit orchards: SCU aids fruit quality by maintaining balanced nitrogen levels right until harvest without potential issues from foliar urea applications.

Potential Improvements to SCU Technology

While SCU has certainly delivered major environmental and agronomic advantages since its market introduction, research continues on improvements. Areas attracting interest include developing newer coats to precisely tailor nitrogen release profiles for various soils and agro-climates, adding micronutrients or plant growth regulators, investigating biodegradable alternatives to sulfur, and evaluating SCU in precision agricultural systems where variable applications are utilized. With further innovations, sulfur coated urea has plenty of room still to optimize global food production sustainably into the future.