The Rise of Flexible Hybrid Electronics

Flexible hybrid electronics (FHE) is an emerging field that combines the functionality of integrated circuits with the mechanical properties of flexible substrates. With advances in materials science and manufacturing techniques, FHE promises to revolutionize many industries by enabling new applications not possible with rigid electronics. Let’s take a deeper look into this exciting new technology.

What are Flexible Hybrid Electronics?

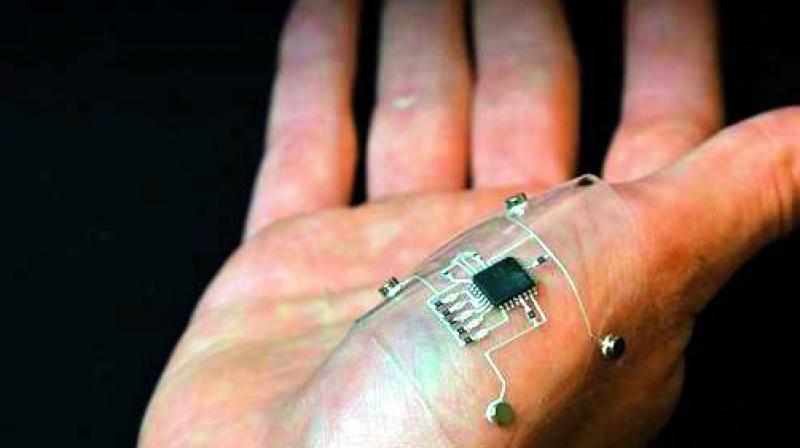

Flexible hybrid electronics refers to flexible circuit assemblies that contain both electronic and mechanical components. These circuits are constructed on thin, flexible plastic or polymer substrates as opposed to rigid printed circuit boards (PCB). The key components include semiconductor chips or dies, thin film batteries, displays, sensors and conductive interconnects all embedded or deposited on bendable substrates.

The silicon chips and other discrete electronic components are integrated with thin-film passives and interconnects formed using techniques such as printing, deposition or etching. This hybrid approach allows for incorporating both conventional rigid electronics and newly developed soft and stretchable components. The end result is fully functional circuits that can conform to curved surfaces, stretch, bend and even sustain damage without compromising performance.

Enabling Technologies

Over the past decade, major advances have been made in the materials, devices and manufacturing processes required to develop flexible hybrid circuits. Some of the key enabling technologies include:

– Flexible plastic and bio-polymer substrates: Materials such as polyimide, parylene and ecoflex have high tensile strength yet are thin and lightweight and can withstand flexing, twisting and stretching.

– Printed and deposited electronics: Methods like inkjet printing, gravure printing and vapor deposition allow printing thin-film electronic features and passives on plastic films with minimum waste. Conductive inks made from nanoparticles of silver, carbon or copper form flexible electronic connections.

– Stretchable and biointegrated electronics: Developing stretchable conductors, organic transistors and display pixels made from elastic composites, liquid metals and ionic gels enables true stretchable circuits. These can integrate with soft biological tissues.

– Hybrid integration techniques: Connecting rigid chips to flexible interconnects using techniques like wafer level chip scale packaging, chip-on-flex and flip chipping embed discrete silicon into soft circuits.

– Manufacturing technologies: Roll-to-roll processing, multi-step self-alignment and transfer printing enable low-cost, high throughput manufacturing of FHE on industrial scales.

Applications of Flexible Hybrid Electronics

Due to their mechanical compliance and design flexibility, FHE open up entirely new application spaces across several industries:

Biomedical Devices

– Wearable sensors: devices integrating sensors to monitor vital signs, hydration, movement without restricting the user.

– Medical skin patches: for non-invasive drug delivery, continuous patient monitoring and tissue regeneration.

– Flexible implants: microfluidic organ-on-chip platforms provide physiological tissue models to better understand disease mechanisms.

– Smart bandages: enhanced wound dressingsintegrate temperature, moisture and chemical sensors.

Consumer Electronics

– Flexible displays: from e-papers, electronic skins to fully rollable displays enabling new form factors like wraparound screens.

– Smartphones/tablets: possible to develop devices with folding or rollable formats providing more compact sizes.

– Smart home: sensors to monitor home environment, vocal interfaces like Amazon Alexa on various surfaces.

Industrial/Automotive

– Structural health monitoring: integrated circuits into vehicles, bridges allow real-time health tracking and predictive maintenance.

– IoT/RFID tags: electronic labels, logistics/supply chain management applications benefit from conformable tagging.

– Wearables: on-body sensors, HMI devices for industrial workers provide hands-free computing.

Outlook and Opportunities

Annual investment in flexible hybrid electronics continues increasing each year as technology maturity level grows. The global FHE market valued at $1.5 billion in 2021 is projected to reach $20 billion by 2030 buoyed by use in biomedical, consumer electronics and other applications.

Many companies worldwide now offer commercial products incorporating FHE technologies within their core capabilities. Yet substantial research in materials science, manufacturing scale-up and commercialization of new application spaces will be needed in the coming decade for this innovative field to reach its full transformative potential. With continued progress, flexible hybrid technologies could ultimately drive paradigm shifts across industries.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it