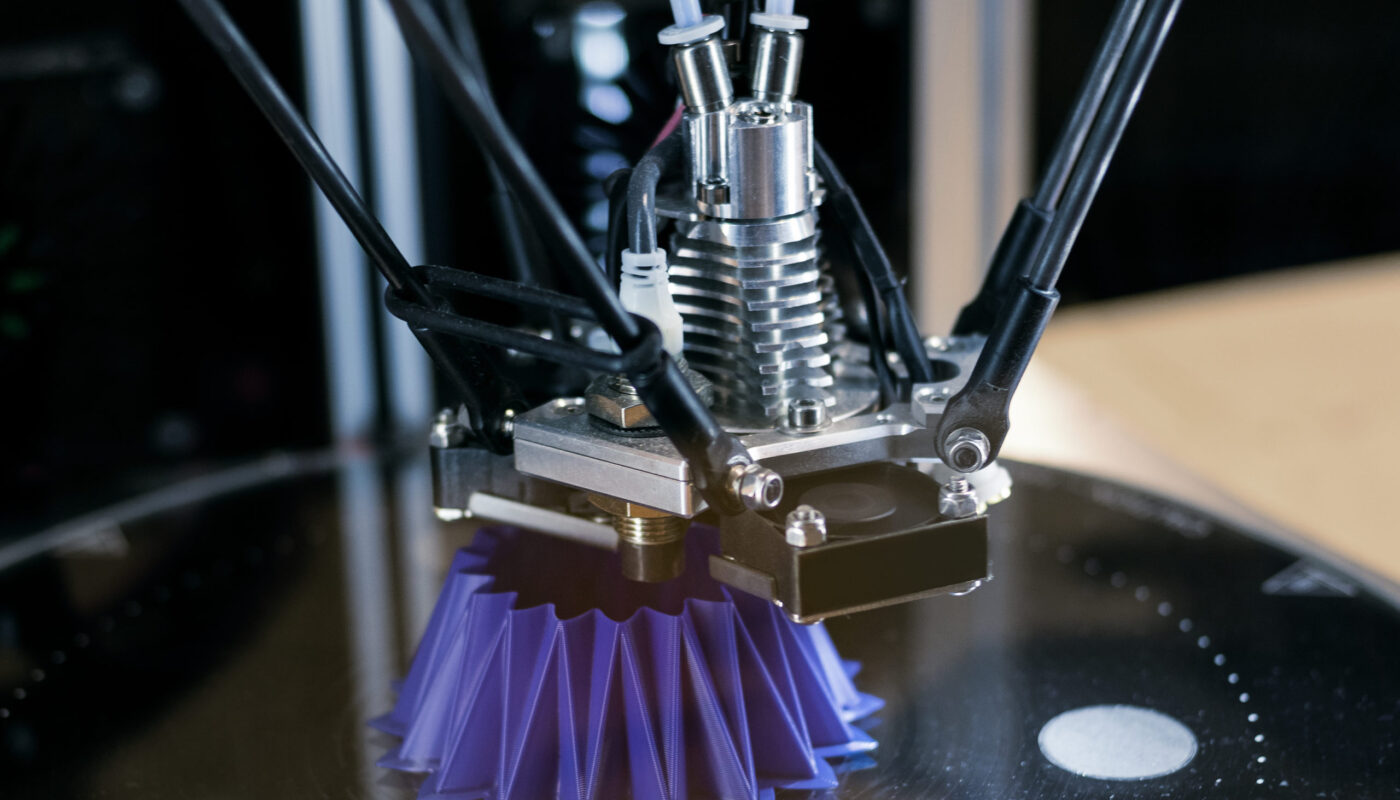

Additive manufacturing, also known as 3D printing, involves layer-by-layer deposition of materials such as plastics, resins and ceramics to manufacture complex geometries for industrial and consumer applications. Polymers are widely used in additive manufacturing as they provide excellent performance properties. Commonly used thermoplastic polymers include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polyamide 11 and polypropylene. Thermoplastic polymers have high strength, toughness, and corrosion resistance, making them suitable for durable applications in aerospace, automotive and medical industries. Photopolymers like polyjet resins are also favored in additive manufacturing due to their ability to be cured by ultraviolet light, resulting in highly detailed complex parts applicable for jewelry, rapid prototyping and dental industries.

The global Polymers for Additive Manufacturing Market is estimated to be valued at US$ 337.84 Mn in 2023 and is expected to exhibit a CAGR of 23% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

The growing adoption of 3D printing polymers across industries is a major trend. Polymers are increasingly replacing metals in additive manufacturing owing to higher design freedom, lower cost and weight benefits. In aerospace industry, polymer 3D printed parts are being used in aircraft interiors, engine components and structural applications to reduce weight. In automotive, composite polymers like carbon fiber reinforced PLA can print high strength complex parts. Healthcare industry uses polymers for printing surgical guides, dental aligners and prosthetics. With the rising customer demand for personalized and customized products, polymers are expected to play a key role in enabling mass customization through additive manufacturing.

Porter’s Analysis

Threat of new entrants: The threat of new entrants in the polymers for additive manufacturing market is moderate. Requirements for advanced technologies and significant investments pose barriers to entry.

Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of numerous product options from various manufacturers in the market.

Bargaining power of suppliers: Suppliers have low to moderate bargaining power as there are many raw material suppliers in this market.

Threat of new substitutes: New substitutes pose low threat as 3D printing polymers have few close substitutes.

Competitive rivalry: The rivalry in the polymers for additive manufacturing market is high due to expansion of production capacities by major players.

Key Takeaways

The Global Polymers For Additive Manufacturing Market Size is expected to witness high growth over the forecast period 2023 to 2030. The market size for polymers for additive manufacturing is projected to reach around US$ 337.84 Mn in 2023 and grow at a CAGR of 23% during the forecast period.

Regional analysis: North America dominates the global polymers for additive manufacturing market and is expected to continue dominating over the forecast period. The growth in the region can be attributed to rapid technological advancements and increasing adoption of additive manufacturing solutions across industries. Asia Pacific is anticipated to be the fastest-growing market, owing to rising demand from countries like China and India.

Key players: Key players operating in the polymers for additive manufacturing market include Arkema S.A., Covestro AG, DuPont, Inc., EOS GmbH, Evonik Industries AG, INTAMSYS, Prototal Industries, Stratasys Ltd., BASF SE, Saudi Basic Industries Corporation (SABIC), Huntsman International LLC., NatureWorks LLC. These players are focusing on new product launches and expansion strategies to gain a competitive edge in the market.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it