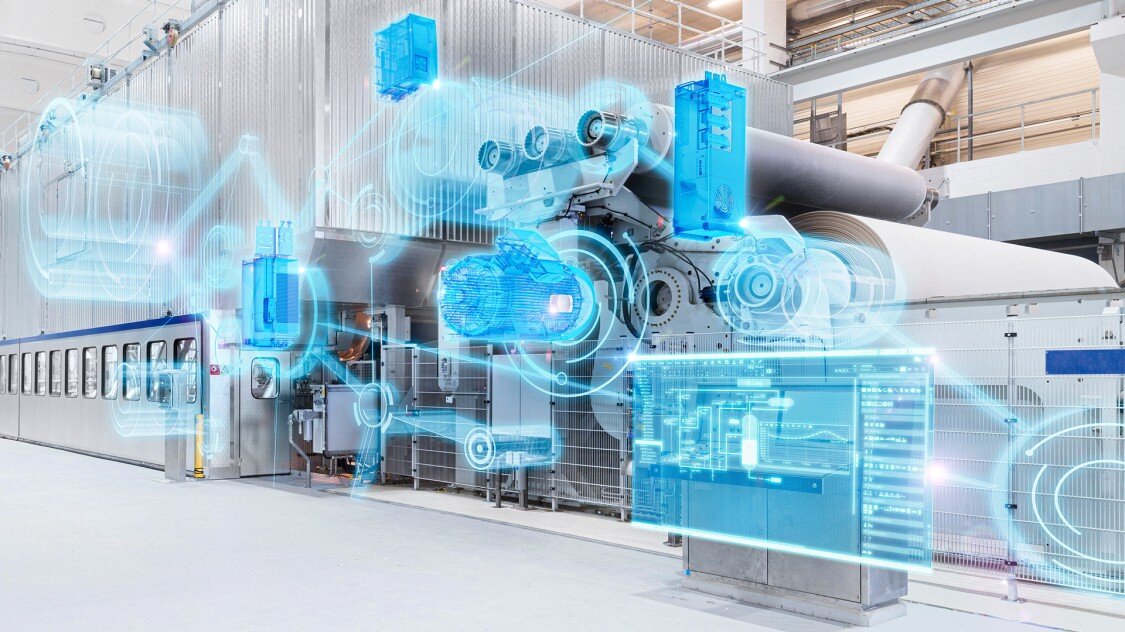

Machine condition monitoring is the process of monitoring the condition of operating industrial machinery to identify potential maintenance needs or reliability issues before breakdowns or failures occur. It involves collecting data from sensors installed on machines, analyzing the data to detect anomalies indicative of issues such as excess vibration, operating temperatures, acoustics, oil analysis, and other parameters. Machine condition monitoring systems signal the need for maintenance work before failures, allowing predictive and preventive maintenance scheduling. This improves equipment reliability and reduces maintenance costs overall.

Machine condition monitoring is widely used across industries for critical rotating equipment like motors, compressors, pumps, gearboxes, conveyors and other rotating and reciprocating assets. By continuously monitoring machines for anomalies and deviations from normal operating conditions, machine condition monitoring systems allow maintenance staff to proactively address issues before machine failures occur. This reduces downtime and helps maximize asset uptime and productivity. With the use of wireless connectivity and cloud/edge computing, machine condition monitoring data can now be analyzed remotely as well. The increasing need for predictive maintenance techniques to optimize asset reliability and minimize downtime is a key factor driving growth of the global Machine Condition Monitoring Market.

The global Machine Condition Monitoring Market is estimated to be valued at US$ 3965.6 Mn in 2023 and is expected to exhibit a CAGR of 5.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

One of the key trends driving growth in the machine condition monitoring market is the increasing adoption of wireless condition monitoring systems. Traditional wired condition monitoring systems require extensive cabling which increases installation and maintenance costs. Wireless systems eliminate cabling needs and allow easy installation on mobile assets as well. They make monitoring of remote or hard to reach assets more feasible. Wireless condition monitoring systems leverage wireless technologies like Bluetooth, WiFi, cellular networks etc. to transmit sensor data to dedicated monitoring devices or cloud platforms. This growing popularity of wireless systems for their flexibility and ease of use is supporting revenue growth of the machine condition monitoring market.

Porter’s Analysis

Threat of new entrants: Low barriers to entry make the threat of new entrants moderate. Existing competitors have established brands and distribution networks.

Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of substitute products. However, switching costs are low.

Bargaining power of suppliers: Suppliers have low to moderate bargaining power as there are many component manufacturers and raw material suppliers.

Threat of new substitutes: Threat from new substitutes is low as machine condition monitoring technologies have few substitutes that can deliver the same functionality.

Competitive rivalry: The machine condition monitoring market is moderately competitive due to the presence of global and regional players. Players compete based on technology, services, and price.

Key Takeaways

Global Machine Condition Monitoring Market Size is expected to witness high growth.

The global Machine Condition Monitoring Market is estimated to be valued at US$ 3965.6 Mn in 2023 and is expected to exhibit a CAGR of 5.8% over the forecast period 2023 to 2030.

The North American region dominates the global machine condition monitoring market and is expected to grow at a CAGR of around 5% during the forecast period. The presence of major players and advanced industrial infrastructure boost the demand.

Key players operating in the machine condition monitoring market are Applied Sciences Inc., Argon, and others. Applied Sciences Inc. offers vibration monitoring and analysis solutions for rotating equipment and machines across industries. Argon provides machine monitoring products and services like vibration monitoring devices, systems, and cloud-based software.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it