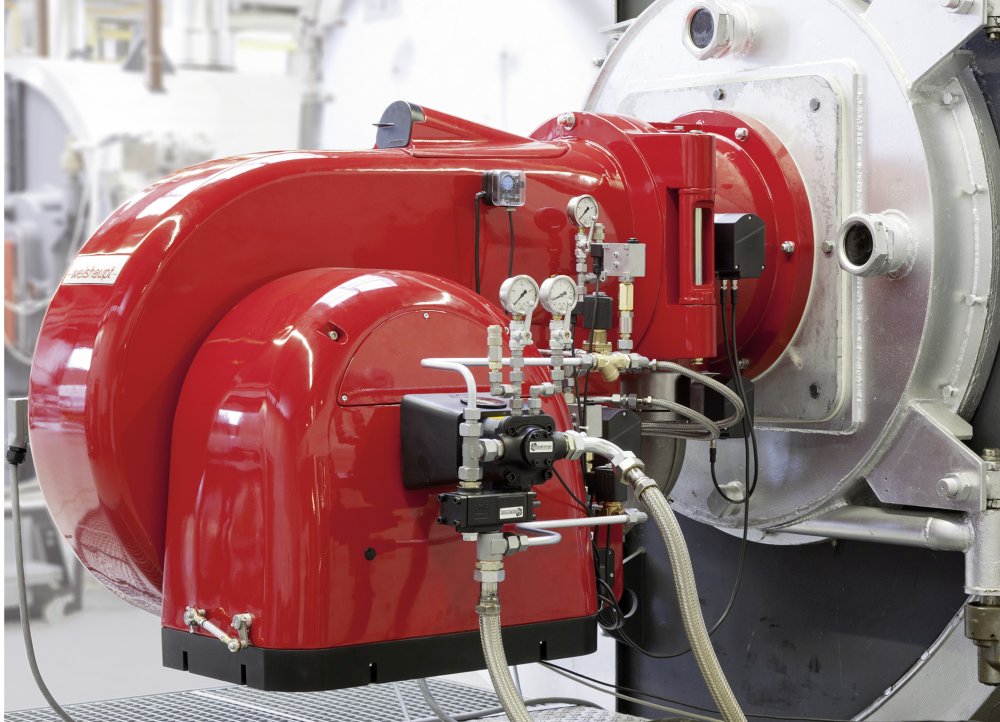

Industrial burners, also known as process burners, are combustion devices used in various industrial processes such as boilers, furnaces, and ovens to produce heat through burning of fuels like natural gas, fuel oil, and gas oil. They are compact energy-efficient burners used in industrial applications to provide heat through combustion. The global industrialization has led to an increase in the production of various goods and material in industries like iron & steel, petrochemicals, oil & gas, cement, ceramic, which drives the need for industrial burners to provide heat treatment through combustion.

The global Industrial Burner Market is estimated to be valued at US$ 3.2 billion in 2023 and is expected to exhibit a CAGR of 5.5% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

Rapid industrialization has been a key trend boosting the industrial burner market growth over the years. The surging demand for various goods and materials produced by industries such as iron & steel, petrochemicals, cement, oil & gas, ceramic etc. has increased their production levels. This has led to an augmented need for heat treatment processes which employ industrial burners for combustion applications. According to World Bank data, the global industrial production index grew by 4.3% in 2021 compared to the previous year. The industrial output is expected to observe continued growth in the coming years due to rising investments in infrastructural projects, increasing manufacturing activities especially in developing economies of Asia Pacific and Middle East & Africa. This will propel the demand for industrial burners during the forecast period.

SWOT Analysis

Strength: Industrial burners have become more efficient in terms of fuel consumption and emissions. They help reduce energy costs for manufacturers.

Weakness: High initial investment costs associated with purchasing and installing advanced industrial burners. Frequent maintenance and servicing requirements add to the operating costs.

Opportunity: Growing demand from industries such as oil & gas, chemicals, food processing, and metals & mining will drive the adoption of new burners. Regulations on emissions and energy efficiency also create opportunities.

Threats: Availability of alternatives like electric heaters and cheaper imports from Asia-Pacific can threaten market share. Economic slowdowns may lead to delay or cancellation of capacity expansion projects.

Key Takeaways

The Global Industrial Burner Market Size is expected to witness high growth.

Regional analysis: Asia Pacific region currently holds the largest share of the industrial burner market owing to strong presence of manufacturing industries in countries like China, Japan, and India. Countries like China, Japan, and India have emerged as major markets and fastest growing regional markets for industrial burners.

Key players operating in the industrial burner market are Alzeta Corporation, ANDRITZ, Baltur S.p.A, Bloom Engineering, Forbes Marshall, Foster Wheeler AG, Hudson Products (Honeywell International Inc.), Limpsfield, Mitsubishi Hitachi Power Systems, Oilon, Osaka Gas, QED Combustion, and Selas Heat Technology Company. Leading market players are focusing on new product launches, partnerships, and expansions to gain a competitive edge and meet the increasing demand from manufacturing industries across regions.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it