The pharmaceutical industry is on the cusp of a major transformation driven by digital technologies and new manufacturing processes collectively called Pharma 4.0. These new innovations are poised to revolutionize every step of the drug development and manufacturing process, from R&D to production to supply chain management. Pharma companies that embrace Pharma 4.0 stand to gain significant competitive advantages in efficiency, quality, and customer satisfaction.

Digital Transformation in Pharma R&D

Pharma R&D has traditionally been a lengthy, expensive process relying heavily on trial and error experimentation. Pharma 4.0 uses tools like artificial intelligence, machine learning, big data analytics and digital twins to streamline drug discovery and development. Computational models can now simulate molecular interactions and screen billions of potential drug combinations in silico, dramatically reducing the time spent on wet lab experiments.

Advanced data analytics allows researchers to gain actionable insights from vast datasets on genes, proteins, chemical compounds and past clinical trials. AI assistants can also automate routine lab tasks like sample preparation and analysis to boost researcher productivity. Companies are also developing “digital twins” – comprehensive virtual models of biological systems that integrate multi-omic datasets to better understand disease mechanisms and predict drug efficacy. These digital tools are accelerating every stage of the drug pipeline from target identification to lead optimization and preclinical testing.

Automating Pharmaceutical Production

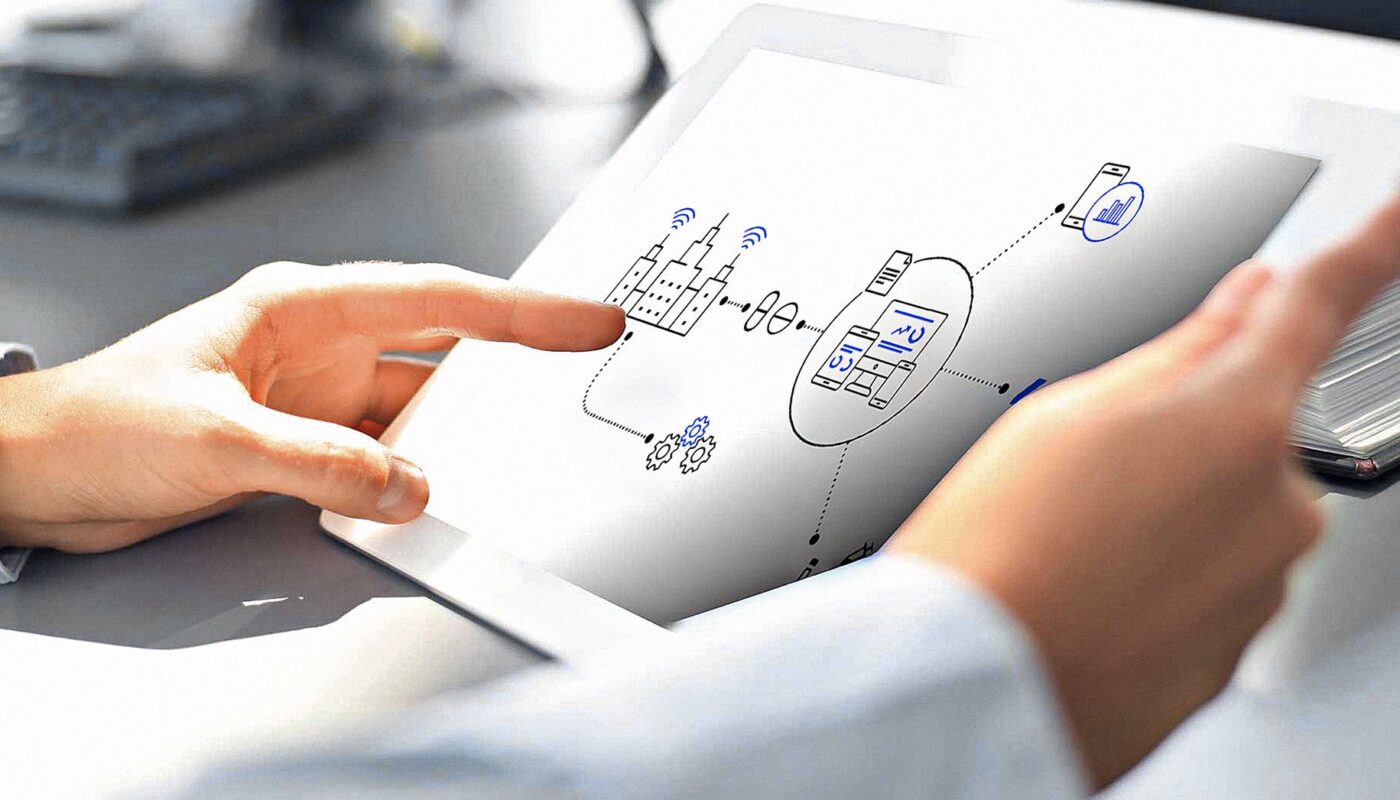

In pharmaceutical manufacturing, Pharma 4.0 relies on automation, Internet of Things (IoT) sensors, advanced robotics and predictive maintenance tools. Automated robotic arms, driverless vehicles and self-optimizing production lines are replacing labor-intensive manual tasks to improve efficiency, flexibility and quality control. IoT sensors continuously monitor environmental conditions and machine performance, allowing real-time optimization and remote monitoring of production facilities.

Predictive maintenance algorithms analyze sensor data to detect anomalous trends and predict equipment failures even before they occur. This predictive approach minimizes downtime for unexpected repairs or validations. End-to-end digitization of manufacturing data also enables full traceability of ingredients and environment throughout production. Emerging technologies like 3D printing can automate personalized drug production in smaller batches. Overall, Global Pharma 4.0 promises higher production transparency, reliability and compliance with stringent regulatory standards for drug quality.

Blockchain and Integrated Digital Supply Chains

Blockchain, a distributed ledger technology, has promising applications for supply chain transparency and traceability across the pharma sector. When pharmaceutical ingredients, components and finished products are tracked using an immutable blockchain record, it eliminates the risks of counterfeits, grey market diversion and breaks in the cold chain. Real-time inventory and order management also improves overall supply chain visibility, agility and demand forecasting.

Pharma companies are working to develop integrated digital supply chain platforms combining IoT sensor data, blockchain ledgers and predictive analytics. This will establish a virtual shared network between drug makers, CROs, logistics providers and distributors. Any stakeholder in the network, from ports to packaging plants, can access accurate digital records of material movements in a verifiable and tamper-proof manner. Regulatory compliance is also enhanced through full digital documentation of compliance with storage, transport and stability conditions. Overall, blockchain helps reinforce trust across complex global pharmaceutical supply chains.

Adopting Pharma 4.0 for a Sustainable Future

While Pharma 4.0 offers vast potential gains, successful transformation will require substantial investments and operational changes. Legacy systems will need to be integrated with new digital infrastructure and processes re-engineered accordingly. Building multi-disciplinary digital skills among employees is another challenge that companies are addressing through extensive training programs. Strategic partnerships will also be important to leverage external technical expertise during implementation.

Regulators play a key role in facilitating Pharma 4.0 adoption through guidance on digital validation approaches, data privacy standards and remote monitoring acceptance. Overall industry collaboration is important to establish reference architectures, standards and an interoperable Pharma 4.0 ecosystem. Countries are incentivizing early digital adopters through tax rebates, providing an impetus for pharmaceutical firms to accelerate their journeys towards Industry 4.0 compliance.

The pharmaceutical industry’s transition to Pharma 4.0 aims to develop more effective and affordable treatment options for patients worldwide in a sustainable manner. By optimizing operations across the value chain, companies will be able to re-invest productivity savings into R&D for precision medicines, rare disease therapies and vaccines. With coordinated efforts among stakeholders, Pharma 4.0 holds immense promise to drive the next phase of innovation in serving global healthcare needs. The future of pharmaceuticals is digital.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it