French fries, also commonly known as chips in some parts of the world, are one of the most popular side dishes enjoyed across the globe. Whether as an accompaniment to burgers and sandwiches or on their own as a snack, fries are a staple in many people’s diets. However, producing fries at an industrial scale to meet the large demand can be a labor-intensive process if done manually. This is where automated fries processing machines come in to help streamline production while maintaining quality and consistency.

History of Automation in French Fries Production

The automation of french fries production first started in the 1960s when potato slicing machines were invented to speed up the slicing process. Early machines could slice potatoes into strips but the cuts were often irregular. Through the 1970s and 80s, slicing technology improved to deliver more uniform fries shapes and sizes. Peeling machines were also developed to remove potato skins faster than manual peeling.

By the 1990s, fully automated fries processing lines emerged which could perform multiple steps like washing, peeling, slicing, washing, blanching, freezing and packaging in a continuous workflow. This helped commercial producers drastically improve output while reducing labor costs. Today’s advanced systems integrate computers and sensors for highly precise slicing and sorting capabilities. Overall, automation has increased fries production efficiency over tenfold compared to manual methods.

Components and Capabilities of Modern French Fries Processing Machines

A typical automated fries processing system incorporates several key components working in an integrated assembly line setup:

– Potato Pre-Processing: Washing and grading machines clean and sort potatoes by size before feeding them into the line. Peeling drums gently roll potatoes against an abrasive surface to remove skins.

– Slicing: Computer-controlled slicing belts or drums cut potatoes into thin strips of precise thickness and length. Ultrasonic sensors detect any irregular slices for removal.

– Water Treatment: Potato strips are transported via conveyors through flumes to rinse away starch and bacteria. Chlorine may be added to kill microbes.

– Blanching: Fries are partially cooked in hot oil or water baths to deactivate enzymes and soften texture before freezing. Times and temperatures are closely monitored.

– Freezing: Individual Quick Freezing (IQF) tunnels blast strips with freezing air to quickly freeze and prevent clumping.

– Seasoning: Robotically controlled spinners season cooled fries with desired mixes like salt or spice before packaging.

– Detection and Removal: Optical scanners detect defects like discoloration or rot for automatic sorting and diversion of substandard product.

– Packaging: Fully automated lines employ form-fill-seal machines to rapidly vacuum pack frozen fries into retail bags or pails. Case packers collate bags for shipping.

– Quality Control: On-line monitoring systems connected to PLCs and computers sample batches for attributes testing and statistical analysis of yields, weights and more.

Benefits of Automated French Fries Production

The numerous advantages offered by automated french fries processing solutions have encouraged their widespread adoption:

– Increased Capacity – Machines can process over 10,000 pounds of potatoes per hour compared to 500 pounds by hand.

– Consistency – Uniform cuts, seasoning, moisture levels and packaging ensures consistent quality batch after batch.

– Food Safety – Processors gain tighter control over hygiene through automated washing and minimal human contact.

– Labor Savings – Fewer employees are needed for operation and maintenance versus manual labor crews.

– Waste Reduction – Optical scanners reduce yield losses from removing unusable product.

– Versatility – Reconfigurable lines can produce various fries styles, servings and specialty flavors.

– Traceability – Integrated systems facilitate full batch tracking from origin to shipping for recalls if needed.

The Future of French Fries Machinery

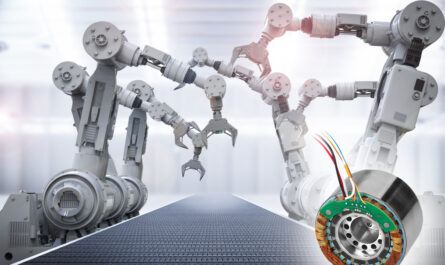

With the popularity of french fries showing no signs of slowing, producers are continuously innovating equipment to boost output further. Advances in robotics, artificial intelligence, 3D computer vision and the Industrial Internet of Things are finding their way into updated systems. Technologies like these promise to:

– Optimize cutting patterns for increased yields from each potato

– Automatically customize production in real-time for peak seasonal demand fluctuations

– Continuously self-check performance and order replacement parts autonomously

– Remotely monitor global line status and collaborate across remote teams

– Develop unique differentiating value-added fries varieties

In summary, automated french fries processing machinery has revolutionized an industry previously reliant on manual labor. Ongoing automation is set to raise productivity to even higher levels while ensuring consistent quality and food safety worldwide.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it