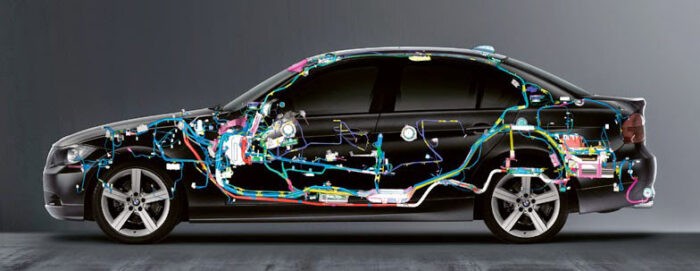

An automotive wiring harness is a complex assembly of electronic components and cables that transmit signals or power (or both) in a motor vehicle. It is often referred to as the “nervous system” of the vehicle as it disseminates information gathered by sensors to electronic control modules which then control various functions of the vehicle. The design and engineering of wiring harnesses is of utmost importance to ensure safe, efficient, and reliable operation of modern motor vehicles that have continued to become increasingly dependent on electronics and computerization.

Rise in Electronics and Complexity

As Automotive Wiring Harness technology advances, the integration of electronics in vehicles has risen exponentially. Features such as anti-lock braking systems (ABS), traction control, advanced driver assistance systems, infotainment and navigation systems have become commonplace. This has led to a massive increase in the amount of wiring required in cars. Early automobiles may have had just a few cables running around but present-day luxury cars can have over 5,000 metres of wiring! With each new introduction of additional electronic controls and sensors, the complexity of wiring harnesses also increases manifold. Proper design and layout is vital to avoid issues related to electromagnetic interference, short circuits, wear and tear over long usage.

Material Science Considerations

To withstand the harsh under-hood automotive environment, wiring harnesses use specialized insulating materials that are flame retardant, weather resistant and able to operate under wide temperature variations. The most common insulation material is cross-linked polyethylene (XLPE) which offers good abrasion resistance and toughness. Thermoplastic elastomers (TPE) and ethylene-propylene-diene monomer (EPDM) compounds are also used for insulation coatings that can flex without cracking. The choice of conductor material is copper for its high conductivity and corrosion resistance properties. Aluminium and tin-plated copper find some usage as well. The harnesses also utilize nylon, PVC and thermoplastic olefin jacketing and binders to bundle cables together and provide additional protection from chafing or moisture. Continuous upgrades in material science help optimize wiring harness durability.

Design and Manufacturing

The design stage is of utmost importance to develop an efficient wiring layout that minimizes length of wiring used while preventing bottlenecks or restrictions to movement of components. 3D computer-aided design (CAD) software allows virtual modeling of harness routing before physical assembly. The wires are printed or stamped with identification codes according to automotive standards. Precision injection moulding technique is used to manufacture insulating connectors and junction blocks with closures. High volume automated assembly lines splice and join individual wires into complete harnesses. Robotic arms efficiently bundle cables using tie wraps or spiral wrap binding. Automatic crimping machines fasten quick connectors to cable ends. Quality checks involve testing for continuity, insulation resistance and bending/abrasion resistance before packaging and shipping.

Application in Various Systems

Each assembly or function in a vehicle requires dedicated wiring – from ignition systems to advanced driver-assistance controls. Engine harnesses contain thin gauge wires to sensors measuring throttle position, crankshaft angle etc. Thick power cables connect the battery and alternator. Body control modules get fed information on door/window switches, seat heaters, alarms etc. Dash area networks comprise wiring for infotainment displays, HVAC and instrument controls. Data transmission is becoming more common rather than point-to-point wiring with technologies like Controller Area Network (CAN) bus and Ethernet. Heavy duty wiring endure high temperatures near the engine while flexible harnesses allow suspension/steering movement. Careful routing and shielding minimizes electromagnetic interference issues. The complex coordination of different wiring systems is engineered to precise reliability levels.

R&D for Future Vehicle Technologies

With vehicle technologies advancing towards electrified drivetrains, autonomous driving capabilities and enhanced connectivity, innovative wiring harness designs tailored for new applications are being researched. Solid state battery packs require specialized sense/load sharing harnesses. Plug-in hybrids and EVs need high voltage insulation and routing. Sensor fusion and computer vision systems utilized by advanced driver assistance systems (ADAS) rely on robust data cables. Vehicle-to-vehicle and vehicle-to-infrastructure communication standards will integrate wiring for dedicated short range communication (DSRC), Wi-Fi and cellular connectivity. Standards like ISO 26262 for automotive functional safety are catalysts for improved electromagnetic compatibility, reduced weight and installability of new wiring systems. Continuous R&D ensures wiring harness technology keeps pace with diverse emerging automotive technology trends.

The automotive wiring harness forms the backbone of information and power distribution network within modern vehicles. Advances in electronics and increasing vehicle electrification have exponentially raised the complexity of harness design with stricter performance targets. Continuous innovation in materials, manufacturing and systems integration spearheads the evolution of this critical component. As automotive technology enters new frontiers, research on wiring harness technologies tailored for futuristic applications will remain pivotal. Standardization efforts concurrently aim to enhance overall quality, reliability and safety.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it