The Growth of Flexible Packaging

Flexible packaging has seen tremendous growth in the ASEAN region over the past decade due to rising consumer demand and preferences. Flexible packaging options such as pouches, bags, wraps and films are increasingly being used for food, beverage, personal care and other consumer products. The material offers advantages such as lightweight packaging, printable surfaces, and shelf appeal which resonate well with consumers.

According to a recent report, the flexible packaging industry in ASEAN countries contributed over $15 billion in 2019 and is projected to grow at a CAGR of 6-7% till 2025. Flexible packaging now accounts for over 30% of the total packaging market in the region, up from 25% in 2010. Countries like Indonesia, Thailand, Vietnam and Philippines have emerged as top flexible packaging markets due to their large consumer markets and rapid economic growth.

Changing Consumer Habits Driving Flexible Packaging

One of the key reasons for the rising usage of ASEAN Flexible Packaging formats is the changing lifestyles and consumption patterns of ASEAN consumers. With increasing urbanization and dual-income households, consumers demand more portable and convenient packaging options that allow them to consume products on-the-go.

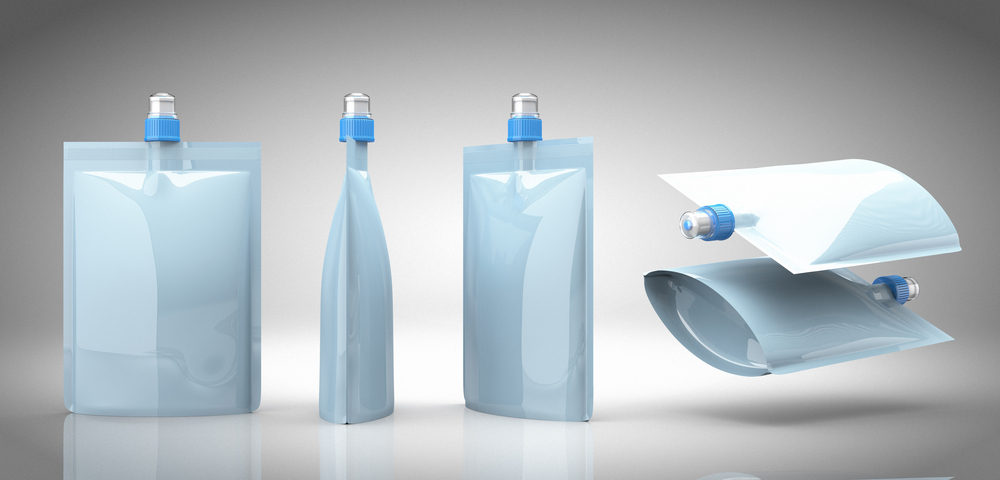

Flexible pouches and bags for foods like snacks, confectionery and ready meals have seen skyrocketing demand as they allow mess-free and easy consumption compared to rigid containers. They effectively address the need for convenient and portable packaging. Similarly, stand-up pouches have replaced rigid bottles and cans for beverages and liquid products thanks to their re-closable and lightweight properties.

Moreover, the desire for smaller pack sizes among consumers to avoid wastage is also propelling flexible packaging. Stand-up pouches, sachets and strips allow manufacturers to offer diverse pack sizes from single serves to multi-pack formats. This has made flexible packaging extremely popular for FMCG products across ASEAN nations.

Advancements in Material and Printing Technology

The rapidly evolving flexible packaging material and printing technologies have greatly expanded the design and functionality possibilities of flexible packs. Metallization, laminations and coatings allow flexible packaging films to achieve barrier properties comparable to rigid containers. This has extended their application to formerly hostile categories such as hot-filled liquids and frozen food.

Digital, multi-color and specialized printing capabilities enable flexible packs to convey intricate and engaging graphics, on-pack promotions and product information much better than before. Structured substrates offer bold textures while specialty inks and foils provide eye-catching vibrant colors and metallic finishes.

The superior print quality and graphics have enhanced the shelf-appeal, brand communication and consumption experience for users. Packs can now act as an extension of brand identities. These advancements are fueling flexible packaging adoption across consumer product segments.

Growing Importance of Sustainability

With rising environmental consciousness, sustainability has become a major consideration for brands as well as consumers while selecting packaging formats. Flexible packaging scores well on this count compared to rigid plastics. Films can be made from renewable resources like plant-based resins and are highly recyclable.

Leading flexible packaging manufacturers are investing in bio-based and commercially compostable materials. Multi-layer films allow effective resource usage with thin gauges. Recycled content is also being increasingly incorporated in packaging films and laminates across the region.

Stand-up pouches, being lightweight, also minimize the environmental footprint during transportation compared to heavy rigid packs. Their space-efficient designs further optimize shipping and logistics. Overall, the improved sustainability performance is positioning flexible packaging as a preferred long-term solution.

Rising Local Manufacturing Capabilities

To cater to the exponential growth, flexible packaging converters across ASEAN have upscaled their production capacities and capabilities over the years. India, Indonesia, Thailand and Vietnam in particular have emerged as major hubs for flexible packaging manufacturing with world-class conversion infrastructure.

Local manufacturers offer the complete flexo, digital and multi-color printing competencies required for complex package designs. They also provide value-added services like lamination, metallization, pouches and bag making under one roof. This has shortened development cycles and ensured just-in-time deliveries for brand owners.

The progressive supportive government policies focused on manufacturing are also attracting flexible packaging machinery and material suppliers to set up local operations. Technology transfers have enhanced the competencies of local workforce. This has not only met the indigenous packaging needs more efficiently but also positioned ASEAN firms to capitalize on export opportunities globally.

The ASEAN flexible packaging market is expected to keep growing at a rapid pace driven by strong consumer product demand, evolving shopping habits and superior performance attributes of flexible packs. Constant material and technology innovations will further expand design possibilities and increase adoption rates. Growing sustainability focus and local manufacturing capabilities will also aid the industry’s expansion. Overall, flexible packaging seems poised to dominate the packaging landscape of the ASEAN region in the coming years.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it